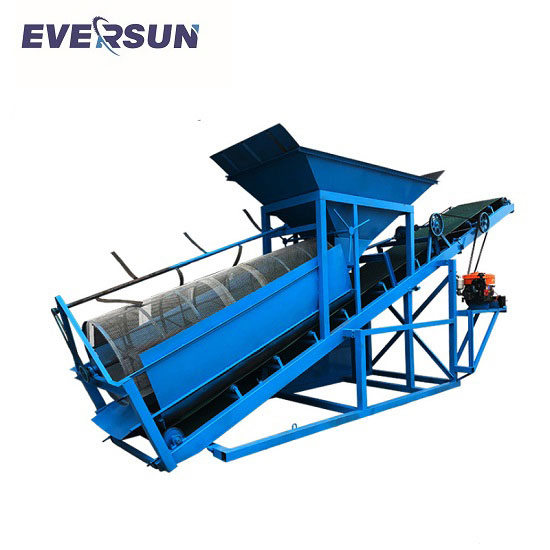

Efficient Sorting Solutions: Discover Sturdy Screener for Sale

Efficient Sorting Solutions: Discover Sturdy Screener for Sale

Blog Article

Boost Recycling Efficiency With High-Quality Screener Tools

In the quest to accomplish higher performance in reusing processes, one can not underestimate the importance of utilizing top notch screener tools. These innovative screening makers provide a variety of benefits that not just enhance product splitting up capability but additionally boost sorting rate and boost accuracy in material classification. Their benefits go past these instant gains. With minimized downtime and upkeep demands, these screeners make certain uninterrupted procedures, thus adding to greater overall recycling productivity. How precisely do these devices achieve such remarkable results? Allow's discover the ins and outs and capability of top quality screener tools to reveal the secrets behind their success.

Improved Material Separation Capability

With its enhanced material separation capability, the top notch screener tools dramatically improves the performance of reusing procedures. This capacity permits the tools to accurately separate various materials based upon their density, shape, and size, leading to a more structured recycling operation.

One of the essential benefits of the boosted product splitting up ability is the capability to different recyclable materials from non-recyclable waste more properly. By efficiently setting apart materials such as plastics, steels, paper, and glass, the screener equipment ensures that valuable sources are not squandered and can be recycled or repurposed. This not only minimizes the amount of waste sent out to garbage dumps yet likewise preserves natural deposits, making the recycling process extra lasting.

Additionally, the improved product separation capacity of the high-grade screener equipment boosts the general top quality of the recycled products. By creating cleaner and higher-quality recycled products, the screener devices contributes to an extra successful and efficient recycling market.

Increased Arranging Speed

One key facet of the high-grade screener devices is its capability to handle a larger volume of products in a shorter quantity of time. This is implemented by the use high-speed motors and reliable conveyor systems that can carry materials rapidly and efficiently through the testing procedure. By decreasing the time it requires to arrange products, the equipment improves general reusing efficiency.

Moreover, the top notch screener devices integrates advanced sensing units and arranging mechanisms that can accurately identify and separate various types of products. These sensing units can identify variants in shape, thickness, and dimension, enabling the devices to quickly and precisely different recyclables from non-recyclables - screener for sale. This not only quicken the arranging process but also enhances the quality of the separated materials

Improved Accuracy in Product Category

Enhanced accuracy in material classification is a critical element of high-grade screener equipment for enhancing reusing performance. Properly recognizing and sorting different sorts of products is important for efficient recycling processes. By using advanced technologies and cutting-edge screening methods, high-quality screeners can attain better precision in categorizing products, leading to boosted recycling results.

One of the crucial benefits of boosted accuracy in material classification is the capacity to different recyclables from non-recyclables much more efficiently. screener for sale. With accurate classification, important products can be determined and drawn out from the her explanation waste stream, minimizing contamination and increasing the total recycling yield. This not only makes the most of the source recovery possibility yet additionally lessens the amount of waste that winds up in land fills

Additionally, precise material classification enables the identification of specific kinds of recyclable materials, such as plastics, metals, or paper products. This permits targeted reusing processes, where different products can be processed separately, leading to higher-quality recycled items. Additionally, boosted precision in material classification helps to satisfy the rigorous top quality requirements set by recycling sectors, making sure that the recycled products fulfill the needed specifications for reuse.

Lessened Downtime and Upkeep

To make sure optimal operational efficiency, high-quality screener tools is designed to reduce downtime and minimize the demand for frequent upkeep. This is attained via using resilient and robust components, advanced innovation, and thoughtful like it style factors to consider.

One means that high-grade screener devices decreases downtime is by integrating self-cleaning mechanisms. These mechanisms aid avoid clogging and blockages, which can result in downtime and expensive maintenance. By immediately clearing away particles and making certain smooth product flow, these self-cleaning attributes permit the equipment to run continually without disturbance.

Furthermore, top notch screener equipment typically consists of built-in diagnostics and keeping track of systems. These systems can detect potential problems and sharp operators prior to they rise into major problems. By supplying real-time details concerning the condition of the equipment, drivers can take positive procedures to decrease and prevent breakdowns downtime.

In addition, premium screener tools is made effortlessly of maintenance in mind. Elements that need regular upkeep, such as belts and displays, are conveniently obtainable and easy to replace. This decreases the time needed for maintenance tasks, permitting operators to obtain the devices back up and running quickly.

Higher Overall Recycling Productivity

One method high-quality screeners improve recycling productivity is by lowering the demand for hands-on sorting. These equipments are furnished with innovative sensors and smart software application that can instantly identify and separate recyclable materials based on their dimension, shape, and structure. This eliminates the taxing and labor-intensive job of hand-operated sorting, enabling recycling centers to process bigger quantities of products in less time.

Additionally, premium screeners can manage a large range of materials, including irregularly and bulky designed things. They are developed to hold up against hefty lots and are furnished with sturdy displays that can properly divide products of different dimensions. This convenience makes it possible for reusing facilities to manage a better selection of waste materials, optimizing their functional effectiveness.

On top of that, high-grade screeners are equipped with attributes such as flexible testing setups and automated cleaning mechanisms. These attributes allow operators to enhance the screening process for various materials, guaranteeing maximum efficiency and reducing downtime.

Final Thought

In conclusion, premium screener equipment is vital for review boosting recycling performance. It supplies boosted product separation capacity, increased arranging rate, and boosted precision in material category.

It uses improved material splitting up capability, enhanced arranging speed, and boosted precision in product category.

Report this page